THERMOPLASTIC HEATING

Convection Oven

The Ultimate Lifting Solution for Moulding Masks

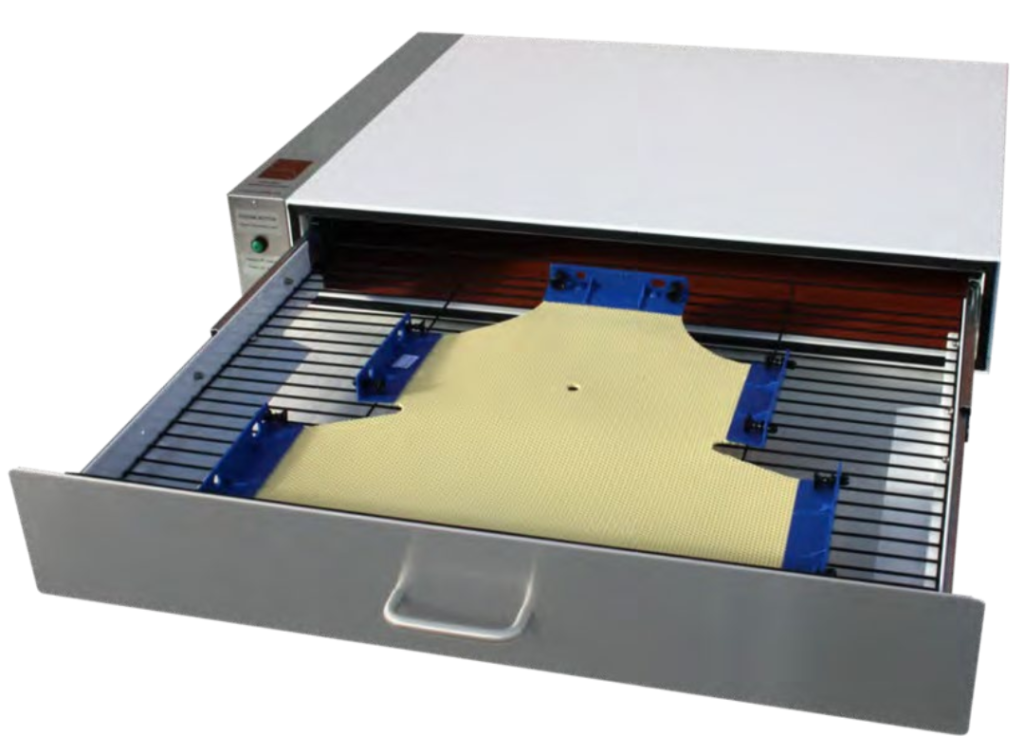

The Dry Heat Convection Oven is an innovative solution for the softening of thermoplastic masks used in radiation therapy. Designed for ease of use, the oven heats quickly, enhancing both productivity and safety during the moulding process.

Its thoughtful design prioritizes patient comfort and hygiene, making it an essential tool for clinical settings. This modern approach streamlines workflows, ensuring better outcomes for both clinicians and patients.

Benefits:

- Convection Heating: Modern alternative to the Hot Water Bath method, delivering uniform heating for ready-to-use thermoplastic masks in just 8-15 minutes.

- Quick Start-Up: Ready to use in just 10 minutes.

- Insulated Design: Minimizes heat loss and maintains a cool exterior for user safety.

- Removes Liquid Hazards: No spillage concerns, constant monitoring or risk of bacterial growth.

- Energy Efficient: Consumes less power than traditional water baths.

- Compact Design: Ideal for crowded departments, fitting seamlessly into any workspace.

- Compatibility: Suitable for all mask types (S-Frame, U-Frame & 5-point masks) and head cushions (Klarity & Orfit).

- User-Friendly: 3″ touch display for automated monitoring & precise temperature adjustments.

- Built-in Timer: Notifies users when the mask is ready.

- Non-Stick Grill: Features a non-stick grill for effortless removal of thermoplastic.

An alternative solution Water Baths

The dry heat of a convection oven offers more consistent and precise temperature control, which speeds up the process and ensures that the material reaches the optimal working temperature of 70°C within just 5 minutes. Regulating temperature on water baths is challenging in contrast.

The masks can become too hot initially and uncomfortable for the patient, and because water doesn’t retain heat well, the masks cool and harden within 60 seconds, making it difficult to fit them properly. Additionally, the wetness of the masks contributes to patient discomfort during the fitting process.

The convection oven allows for 2-3 minutes of shaping time before cooling, giving clinicians more flexibility and precision. It also eliminate the discomfort of water exposure on the face, and keeps the treatment room free from excess humidity, creating a healthier, more hygienic environment

Our solutions are made in Australia

Globalsonics Research is one of few Australian

organizations investing in R&D in the field of nuclear medicine. Our

engineers are directly involved in the design and manufacture of our

technology, showcasing their knowledge and capabilities to manufacture high

quality solutions.